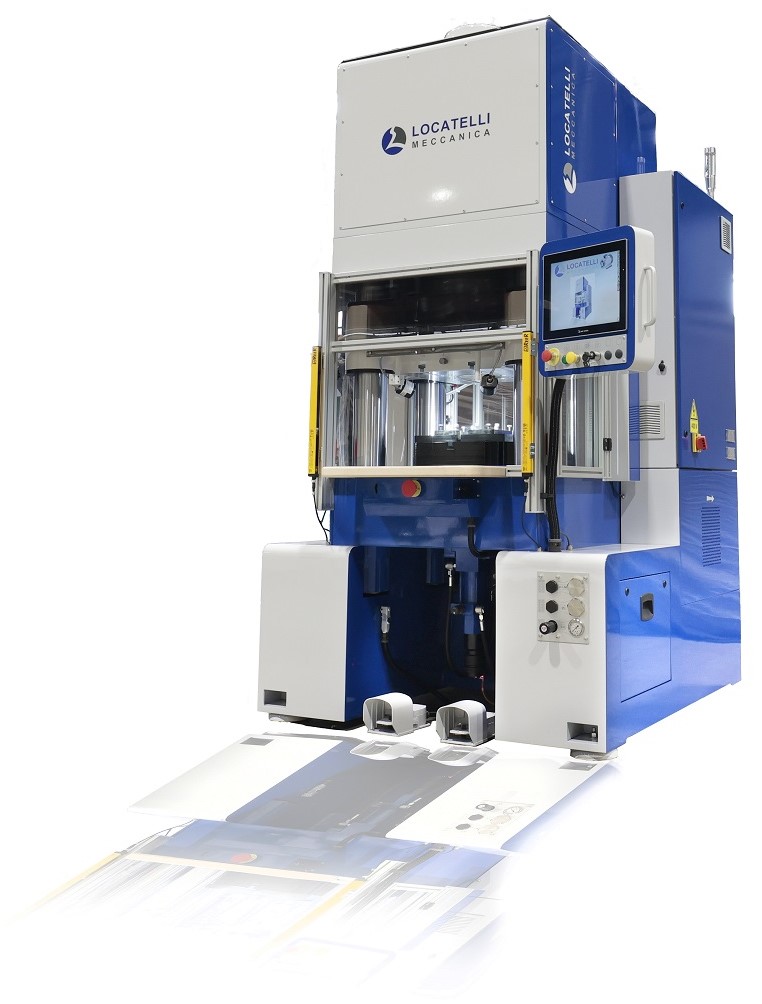

Locatelli Meccanica designs and manufactures High Precision Hydraulic Presses; furthermore, its flexibility makes it possible to build also special Hydraulic Presses and Automatic Lines.

Keeping as central the quality of the service, Locatelli Meccanica has accumulated experience in Metal Sheet Processing with a wide range of solutions, including fully robotized applications for the total automation of the production cycle, such to cover the most specific needs. With the steady improvement of its production structure and thanks to the particular attention to research and development, Locatelli Meccanica has considerably increased the range of its products with successful penetration in the most important international markets.

Locatelli Meccanica Hydraulic Presses are used for Coining, Minting, Blanking, Stamping, Embossing, Sintering, Hot stamping of composites materials and rubber, in the industrial sectors of Jewelry, Spectacle Frames, Automotive, Electronic Industry, Watch Industry and Mechanic Industry in general. All the machines have very low noise and high production capacity; this is due to high-quality materials and particular hydraulic circuits provided with the machines.

The four columns structure of these presses is designed with Finite Elements Method, highly dimensioned and with a high rigidity; the automatically lubricated ram, which slides on the four columns, is guarantee of a perfect parallelism between the two tables and gives a high degree of precision during the pressing.

Pressure control is done through a proportional valve.

Pumps and oil cooling systems are located over the lower oil tank for an easy inspection. Quick response hydraulic plant gives high reliability and reduces the working time.

Based on High Manufacturing Standards, these presses are provided with many options such like Safety Devices, LED light, antivibration feet, low noise pumps, and can be provided with automatic feeding, upper and lower ejectors with hydraulic cushion, blank holder and much more. Personalized options and special modifications can be asked upon specific request.